SP-NE/NET ASTM Type I Ultrapure Water

ASTM Type I Ultrapure Water Purification Systems

"SP NE/NET" - ASTM Type I Ultrapure Water purification Systems.

The industry's most complete water purification solution for highly regulated applications.

When your application requires the ultimate in water purity, "SP" provides the perfect solution.

Consistently delivering water purity of 18.2MΩ.cm and underpinned by the advanced technologies, the "SP" enables you to focus on attaining accurate results while ensuring an uninterrupted work flow.

Typical scientific applications

- ICP-MS(Inductively Coupled Plasma Mass Spectrometry)

- Molecular biology techniques

- Ultra trace analysis

- Electrochemistry

- Electrophoresis

- GFAAS(Graphite Furnace Atomic Absorption Spectrophotometry)

- HPLC

- IC(Ion Chromatography)

- ICP-AES(Inductively Coupled Plasma Atomic

- Emission Spectrometry)

- Mammalian and bacterial cell culture

- Molecular biology

- Plant tissue culture

- Qualitative analysis

Not just a bigger display. A better display

It's one thing to make a bigger display.

It's something else entirely to make a bigger Touch display with brilliant colors and higher contrast at even wider viewing angles.

Online TOC for prevention of organic breakthrough ("SP NT")

Constant real-time Total Organic Carbon(TOC) monitoring* allows you to verify that the system's organic contaminants removal process is operating within specifications.

Several benefits

Oxidation and conductivity measurements occur in the same cell. As a result, the monitor checks that all organics have been oxidized in order to deliver an accurate and reproducible TOC value

An accurate measurement of TOC between 1 and 300 ppb is provided, based on extended calibration.

The design allows performance of the TOC suitability test as required by USP 643 and EP (European Pharmacopoeia)

Premium water delivery

- Each remote water dispenser has a backlit screen enabling the user to check system operation and water quality at a glance.

- Dispenser units are placed on a recirculation loop, and can be located up to 3 meters from the main unit or from the previous dispenser on the loop.

- Easy operation that allows users to select either manual or automatic delivery to save valuable time.

- Dispensers are designed to accommodate all commonly used glassware.

- For hands-free water delivery, an optional footswitch can be connected to the system.

- Press once to start and once to stop

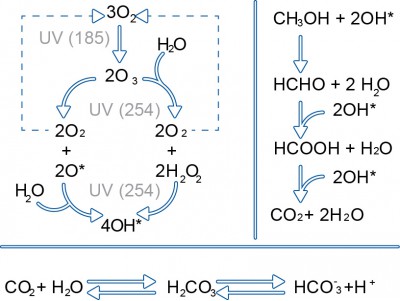

Full Spectrum UV treatment

- Low microbial and organic specification

- High transmittance synthetic quartz sleeve for higher efficiency

- Patented lamp life indicator is designed to predict lifespan according to actual conditions

Technical specifications

| Code |

HL/CR/SP/NE |

HL/CR/SP/NET |

| Model |

"SP-NE" |

"SP-NET" |

| Description |

Ultra-purified water system |

| Power Supply |

Standard configuration - 220V/50Hz |

| Features |

15 l/h output (pure water) |

| 1.5÷2 l/min output (ultrapure water) |

Inlet water requirement:

tap water, >1.0 kg/cm², 10÷40℃ |

| Output water Resistance: 18.2ΜΩ.cm |

| Pyrogens <0,001 EU/ml |

| TOC: 1÷5ppb |

TOC: 1÷5ppb

(online TOC monitoring) |

| Standard Configurations |

Main Unit |

| Water leakage protection sensor |

| Pre-treatment module |

| High pressure pump |

| RO module×2 |

| Dual wavelength UV-lamp 254 nm / 185 nm |

| EDI Module |

| Ultra-purification cartridge |

| Ultrafiltration cartridge |

| Point-of-use filter 0,22 μm |

Water tank 30 litres

including pump and 5-level float sensors |

| Air filter net for tank |

UV-lamp sterilizer for water tank 254 nm

220V / 6 W with quartz sleeve |

| Remote water dispenser with color display |

| N/A |

TOC Online

monitoring module |

Water Purification Systems HL Series - General characteristics

Many laboratories require ultrapure/pure water every day.

We understand how important it is for scientists to obtain a choice of water qualities that range from primary grade, for simple routine washing and rinsing, to ultrapure for the most critical science and analytical applications.

Among others, HF Series applied our expertise gained from years of innovation, to offer water purification systems that prepare water of various specified qualities as reliably, practically and cost-favourably as possible.

This informations outlines the key features of all the products in our range, which are designed to provide water purification systems covering the three different water types required for research and testing applications.

What to look for in an ideal water purification system?

HL Series gives you more:

- Multiple technologies into a system

- A comprehensive sequence of water purification process

- A range of cartridges exists to remove specific types of contaminants

- Optimal for water quality guarantee

- Resistivity monitoring for high-precision measurement of ionic concentration

- TOC monitoring for prevention of organic breakthrough

- Reliability you expect

- Supported by HL/Cheimika worldwide service

- Part of an overall solution that includes design, consumables,instruments and validation

- Execptionally easy to operate

- Easy-to-use graphical interface

- Rapid cartridge replacement

- Convenient pure and ultrapure water delivery

Technical Processes and Features

Water purification is often a complex process that incorporates multiple technologies into a single purification system.

Patented Pretreatment Cartridge

- Compression molding process prevents water leakage risk from your safety

- Column is filled with active carbon integrally removing free chlorine in tap water

- PP cotton removes particles, effectively guarding RO membrane from clogging

- Strengthened pretreatment cartridge & water soften column is optional for hard water

Reverse Osmosis Module

- Highest quality DOW reverse osmosis systems with state of the art spiral membranes

- Remove inorganic ions, bacteria and particulates with high efficiency

- Automated forward and backward rinse to clean the membrane surface ensures stability and durability

- Flow restriction design keeps reverse osmosis membrane wet to maximize its lifespan

High-Strength UV lamp

- Dual wavelength UV lamp ensures organic molecule oxidation and bacteria destruction

- UV lamp is activated only when ultrapure water is produced

- Water inlet at bottom of the cartridge to avoid trapping air bubbles

- Held in a robust and corrosion-resistant stainless steel housing

- High transmittance synthetic quartz sleeve for higher efficiency

Purification Cartridge

- Adoption of high quality precision grade resin

- Dual-column design increases the ion exchange capacity of consumables and minimizes running costs

Ultra-Purification Cartridge

- Adoption of high quality nuclear grade resin

- Polishing catridge removes ionic and organic contaminants below trace levels

- Active carbon supplement* restrain organic level inside the cartridge effectively

*Applicable for HL/CR/SP/303/M

Ultra-Filtration Filter / Micro Filter

- Effectively filter out endotoxin, proteins and nucleases, which is critical for tissue culture, cell culture and media preparation*

- The large ultrafiltration area and automatic surface rinse ensure both a high flow rate and a long service life

- Easily switch to alternative microfilters for different applications

*Ultra-Filtration Filter

Point-Of-Use filter

- 0.22 μm membrane filter farthest eliminates contaminants that might interfere with specific application at dispensing point

Delivered water maintain consistent peak quality and unqualified water is automatically recirculated

More Featured Designs for Applications

Microprocessor Control

- Fully automatic and self-diagnostic system monitors and controls working condition

- PIN-coded access to software set points prevents unauthorized changes to operation or system settings

Comprehensive Sanitization

- Unlike many other systems, HL Series entire fluid pathway is included in the automated disinfection process ensuring complete sanitization

Module-designed Cartridges

- High quality and economical due to disposable integrated purification column design.

- Easy replacement and quick connection.

High precision resistivity meter

- Flow-through structure make sure the real-time measurement of the actual ionic concentration in water

- Low cell constant (0.01cm-1) to ensure optimum measurement accuracy of low ionic contamination

- Automatic temperature compensation (0.1℃ resolution) makes the value displayed on the screen meaningful

Easy-to-read LCD display

- User-friendly LCD provides optimal convenience, with indication on resistivity, reservoirs water consumable changing reminder water quality

Optional strengthened pre-treatment module

20' size long cartridge contrains detergent. Therefore, besides the feature of higher water throughput, feed water with extremely low quality can be properly dealt with.

Contamination-Free Water Tank

- Water level sensor combined with bottom pump enables 5-level automatic water production controls

- Capacity of water reservoir includes 30 l and 60 l. Moreover ultra big 350 l water reservoir is available for special needs

- The water reservoir is made through cylindrical mold and blow molding proces to avoid the generation of velum

- PE material ensure low extractives

- Overflow protection tube eliminates the risck of flooding

- Cone shape bottom guarantess no stagnant water and facilitates easy cleaning

- Optional UV lamp and vented filter maintain consistent purity of stored water and provide effectrive protection against airborne contaminants

Network compatible

RS232 port allows for data collection and permanent record of water quality and system parameters, with date and time, to a PC or printer - essential for compliance with good laboratory practice guidelines.

Simplest operation!

- Just four control keys allow for rapid operational readiness to improve user experience

- Everything else is automatically managed by the built-in microprocessor control system

- PIN-coded access to software set points prevents unauthorized changes to operation or system settings

Rapid cartridge replacement

- One, two, three... rapid cartridge change due to quick connection

- Water purification progresses through separate modules, each with quick connects for simple individual replacement

- Streamlined appearance and intelligent structural design with easy-access door means system can be located under bench

- Quick and easy sanitization and replacement of consumables reduce maintenance time

Reliable work!

- Integrated feedwater check

- Good quality feedwater is a basic requirement for the degree of purity of the water produced, as well as for the long service lives of all purification stages

- An additional measuring cell permanently monitors the conductivity of the feedwater

- Any exceeding of the limiting value is immediately displayed

Conductivity measurement!

- The high-precision conductivity measuring cells are individually measured out and each value deposited in the system

- The electronics are automatically calibrated and controlled prior to each measurement

Temperature compensation!

- Platinum chip temperature sensors with an accuracy of +/- 0.1° C are used here

- The temperature compensation can be switched off. USP requirements are fulfilled and optimal measurement reliability ensured

Flexible dispensing!

- Remote water dispenser with ergonomical design comforts your water delivery experiences

- The height and direction of dispenser is adjustable for different positions

- Action radius is 25cm

- The dispensing pistol can be removed from dispenser arm to expand your working area

- Full recirculation guarantees water quality at point-of-use

- Auto-volume dispense from 100 ml to 60 liters and repeat dispensing

- Foot-pedal activation is available to allow hands-free delivery in a clean room, further reducing the possibility of contamination

Clear information!

- The large easy-to-read LCD display affords the user optimal convenience, with indication on:

- The temperature in °C

- The temperature-compensated conductivity/resistivity of water

- The operating mode status, such as production, stand-by

- Liquid level in water tank

- Consumable changing reminder

Water leakage protection!

Water leakage sensor is linked to the microprocessor system to automatically cut off water input and activate alarm in the situation of leakage.

Space saving!

- Each SP series can be o ptional installed space-savingly under the bench, in a lab table, or mounted directly to the wall (without the need for extra mounting material)

- Remote dispenser can be connected to the main system at a distance of 3 meters

- You can get water from height adjustable arm, or hand-held dispensing at each point-of-use

SP SERIES

Not just a bigger display. A better display

- It's one thing to make a bigger display. It's something else entirely to make a bigger Touch display with brilliant colors and higher contrast at even wider viewing angles.

Online TOC for prevention of organic breakthrough

- Constant real-time Total Organic Carbon(TOC) monitoring* allows you to verify that the system's organic contaminants removal process is operating within specifications

Several benefits

- Oxidation and conductivity measurements occur in the same cell. As a result, the monitor checks that all organics have been oxidized in order to deliver an accurate and reproducible TOC value

- An accurate measurement of TOC between 1 and 300 ppb is provided, based on extended calibration

- The design allows performance of the TOC suitability test as required by USP 643 and EP (European Pharmacopoeia)

*For models with TOC capability

Premium water delivery

- Each remote water dispenser has a backlit screen enabling the user to check system operation and water quality at a glance

- Dispenser units are placed on a recirculation loop, and can be located up to 3 meters from the main unit or from the previous dispenser on the loop

- Easy operation that allows users to select either manual or automatic delivery to save valuable time

- Dispensers are designed to accommodate all commonly used glassware

- For hands-free water delivery, an optional footswitch can be connected to the system

- Press once to start and once to stop.

EDI know-how

Adoption of Electrodeionization (EDI) module brings benefits including lower energy consumption; lower maintenance cost; better ion exchange and no particulates or organic contamination.

The models incorporates state-of-the-art Electrodeionization (EDI) technology to purify the water instead of only using conventional ion exchange.

EDI is an electrically-driven water purification process which involves the use of Ion Exchange Resins and Ion Permeable Membranes. Resins are continuously regenerated by the electrical current and are never exhausted.

What benefits you can get

- Constant high efficient removal of ions and small MW charged organic (Resistivity > 10 MΩ‐cm)

- No exchange of spent resins

- No regeneration chemicals

- Low energy consumption

- Typical <10 watt light bulb

- Low operating cost and low maintenance

Full Spectrum UV treatment

- Low microbial and organic specification

- High transmittance synthetic quartz sleeve for higher efficiency

- Patented lamp life indicator is designed to predict lifespan according to actual conditions